When Lectra went behind the scenes at LVMH

26/03/2015

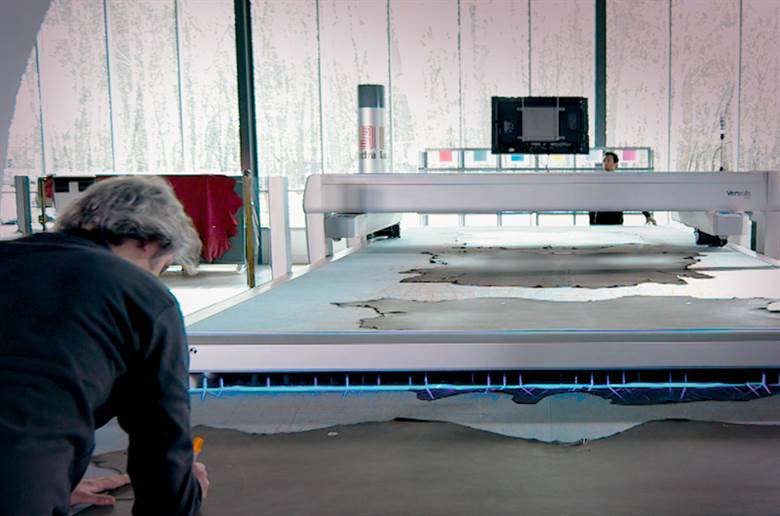

Speaking at the Future of Automotive Leather conference in Bordeaux in March, Mr Harari said: “Versalis was developed with Louis Vuitton and it took more than five years. We had 100 people looking at Louis Vuitton’s processes over that time.”

He said all the hard work had paid off because Louis Vuitton was able to use the new system to make 12% savings in its use of leather owing to the reduced waste Versalis can offer compared to earlier versions of leather-cutting technology. This translated into important savings, Mr Harari explained, because leather accounts for around 60% of all of Louis Vuitton’s production costs.

In addition, he said that the new technology had helped the luxury leathergoods brand achieve greater consistency in the quality of products made in different factories across its production network.