A force for good

Bekir Burak Uyguner is president of his family’s leather manufacturing company, Uyguner Deri, based in Istanbul. He is president of the Turkish Leather Industrialists’ Association and of the Turkish Leather Employers’ Association. He is also a member of the board of directors of the Istanbul Leather and Leather Products Exporters’ Union. On March 13, 2023, he added to this long list of responsibilities by becoming the new president of the International Council of Tanners (ICT).

Congratulations on taking up the presidency of the ICT. What will your priorities be for your two-year tenure?

To promote leather well and to make people understand that we are a force for good. It’s a difficult time, you know. I think you have to be a tanner to feel the pain. I feel the pain; I feel it locally and internationally. One side of the problem is raw material and traceability, and the other part is the new EU regulations for chemicals, because if the EU makes regulations, basically everyone else follows. We are all doing our best to do something with our by-products. We try to do better every day in terms of water use and energy use. Maybe that’s not true of absolutely all the tanners in the world, but if you look at what the Europeans (the Italians, the big guys in Germany, the Austrian guys, the Spanish people) are doing, they take it really seriously. And still in the eyes of the average person a tannery is what they have seen in the famous picture taken in Fes in Morocco.

[Editor’s note: Morocco attracts some 11 million tourists annually. Its oldest city, Fes or Fez, was founded in 789 as was its tanning industry. The dyeing pits in the city centre are a tourist attraction but have no relevance to modern leather manufacture.]

With more scrutiny on greenwashing now, will people come round to understanding the leather industry better?

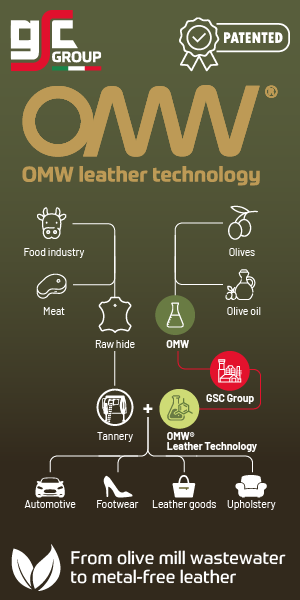

If we don’t push for it, I don’t think so. We are the ones who have to do something about it. Every other day you see stories about material from pineapples, apples, olive leaves and so on. It’s nearly always a non-woven material coated with acrylic and a little of whatever plant they want to mention in the product’s name. What we have to do is to tell our story over and over and over again without getting tired. We have to create some good public relations messages and show people what we are doing.

What should we show?

It seems to me that the news media in many parts of the world wants to show that it’s cool to be vegan. Fine. These people are against meat but it looks as though they are against leather even more than they are against meat. As long there are also some people eating meat, there is no way of avoiding it: we need the leather industry. Brazil is slaughtering 40 million head of cattle per year. It’s probably more or less the same in the US. We have almost 8 billion people in the world and we have more than 1 billion people who are undernourished. They don’t have access to proper food and we cannot waste one molecule of protein. You don’t have to turn everything into a piece of finished leather. Once we learn how to select better in the raw or in the lime, the hides that are not suitable for leather production will be part of food industry. This is how it is in Africa today. Today for our colleagues in Africa, their competition is from people who eat hides. Colleagues in Uganda and Kenya have told me that food sellers there give the butchers money to put more holes in the hides deliberately so that tanners won’t buy them.

In Turkey’s case, how many tanneries are operating across the country at the moment?

The official number was close to 500 bovine and sheepskin tanneries a couple of years ago in seven or eight different clusters, but now tanning is becoming more centralised. The main areas for bovine are Tuzla, Bursa and Gerede. There is also one in Anatolia, in Nigde, and some in Izmir. The volume of hides being tanned in Turkey is increasing because we have built a very strong gelatine and collagen industry. We have five companies producing edible gelatine. Across the whole of Turkey, the volume of hides processed in 2022 was probably around 10 million. It’s not huge but it’s not small. Turkey’s leather and leather products exports had a value of about $2 billion in 2022, between 18% and 20% higher than the corresponding figure for 2021. So 2022 was the real recovery year following covid-19. The figures for the first two months of 2023 have shown further increases, of more than 15%, but we have seen a slowdown since then, mainly because our exchange rate against the dollar is less competitive than last year. We also paid for two salary increases last year and the cost of energy went up. We hope to keep the growth up, but the exchange rate is not helping now.

How many people do these companies employ?

Around 20,000 people work in our tanneries. I cannot give an exact figure for the wider industry.

How many square-metres of finished leather do they produce each year?

Of those 10 million hides, maybe 30% go for soaking and liming and then directly to the gelatine manufacturers. That leaves 7 million hides for producing leather.

How important are export markets for your member companies?

Earnings from exports of finished leather in 2022 were about $300 million. We have a strong shoe industry too. Our shoe manufacturers are mostly small companies rather than big ones but they are good and they export footwear with a value of $1 billion per year.

We know that Russia has long been an important market for leather-sector exporters in Turkey and that trade has continued in spite of the war between Russia and Ukraine. But we also know that the European Union is an important market for Turkey, in particular Germany and Italy. How is it possible to maintain good relationships with all of these trading partners in a time of conflict?

Russia has been a big customer for many years. But we have had our own political tensions with Russia, too, and the relationship has not been as strong since about 2015. Now the export market for Turkish leather is pretty diversified and Russia is no longer the number-one customer. The European Union is number one now and Germany on its own is bigger than Russia. But yes, Russia is an important customer for us; that remains a reality. And today, with all the sanctions that are being enforced on trade between Russia and western countries, Russia is buying more from other markets, and Turkey is probably one of those markets. But we are not seeing any dramatic increase in the numbers.

As you know, the entire world was deeply saddened by the loss of life and devastation that Turkey and Syria suffered after the earthquakes in February this year. If our information is correct, there was little leather and or leathergoods production in the worst-affected regions, but can you say what you think the effect will be on the country as a whole, including the leather industry, as it rebuilds and recovers?

It was very sad. There were only a few leather-sector companies affected and they were small, but it was a very sad situation and the number of casualties [more than 57,000 across Turkey and Syria] was very high. If you look at the overall picture, the regions that were badly affected accounted for 7% or 8% of Turkey’s gross domestic product. That means the rest of the country, which has the remaining 92%, has the capacity to help those regions build themselves back up again. But it was extraordinary: two earthquakes registering more than 7.5 on the Richter scale, both very shallow, hit within nine hours of each other. We feel deep sorrow for our losses but we are strong and we will rebuild.

New president of the International Council of Tanners, Bekir Burak Uyguner. Credit: Uyguner Deri