Accuracy matters

The new president of the International Union of Leather Technologists and Chemists Societies took up the role at the start of 2022. He knows there is much work to do and that war makes most things even harder, but he still speaks optimistically about the leather industry’s future.

In your message as IULTCS president at the start of this year, you expressed a high level of optimism. What effect has the war in Ukraine had on the way you view the rest of 2022?

The tanning industry has been badly affected by the war. First, because energy costs have gone very high. Some tanneries may face restrictions in electricity and gas supply. The second thing is that the war has also had a big impact on the price and availability of chemicals. The experience of my company, ATC, is that we are facing terrible problems with deliveries and the price of some of our raw materials has tripled. Delivery times that used to be two weeks are now two months. Let’s say you want to buy ammonium salts: these are mostly produced in Ukraine and Russia. They produce those salts to make fertiliser for agriculture, but we use them too to make deliming agents. Well, the price has multiplied by four and the quantities available are very limited. The whole leather value chain is being impacted. Tanners who I have spoken to have said their customers want to wait before buying more leather because consumers are afraid of the situation and are reducing their purchases of shoes, handbags and so on. So the tanners, in turn, are putting the purchase and soaking of new hides on hold, saying they will work from wet blue for now because the future is too uncertain.

You highlighted the strong performance of the luxury leathergoods sector, dominated, of course, by major French groups, as one of the reasons you felt positive about 2022. What are the reasons why this sector is so strong?

We have good relationships with the top management in some of those companies. I have been in meetings with them recently and they are still optimistic. They are still producing, selling and exporting a lot and, if you see their turnover and profits, the figures are very impressive. Rich consumers have faced restrictions for two years because of the pandemic and have not been able to travel anywhere and, now that these restrictions are lifting in many places, demand is strong and the success of the big luxury groups continues. Those companies are very strong in marketing. For them it wasn’t a problem that airport shops were closed; they redoubled their efforts to sell in their own-brand shops and the result was people queueing outside to buy things. These companies don’t have enough products to satisfy the demand, which is why, every year, we see new leathergoods factories and new training schools opening, creating hundreds of new jobs in France. They need more leather too and the major calfskin tanneries in France have been owned by the luxury groups for the last ten years or so and they have invested a lot of money in them.

Does this make it hard for small, independent tanneries to compete?

Very hard, but many of those smaller tanneries are not producing calfskin. They work in sheepskin or bovine leather for shoe uppers instead. The most famous French tanners only really buy grade-one hides and don’t bother with the other grades. If you are an independent, family-run tannery you have to try to create value from the other grades too. It takes a lot of effort to make good leather from that material and find customers for it. But in France, at most, we have around 50 tanneries, of all sizes, left. In Italy there are ten times more.

You said there had also been “a commendable recovery” in furniture and footwear. A fall in the use of leather in footwear has been a problem for many years. What are the indications you have seen of a change here?

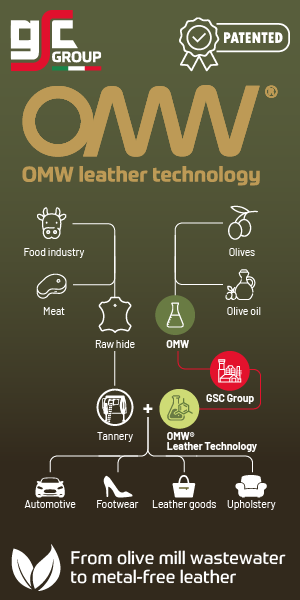

It’s true that the shoe market has been affected for many years by competition from synthetic materials, but tanners are optimistic. We sell chemicals all over the world and this is the message we are receiving from the tanners. They believe the shoe business will come back, that the change will come, even if this is not the market situation yet. And the reason is sustainability. Consumers now understand that shoes made from synthetic materials are a disaster. Leather, on the other hand, uses waste from the food industry and upcycles it. When you buy shoes made from leather, the levels of pollution and environmental impact are very limited, but so many brands choose to use the unfair figures from the Higg Index when trying to calculate carbon footprint. IULTCS is working with other groups such as Leather Naturally and the Leather Working Group to help tanners show accurate figures for leather’s carbon impact. And when they are able to show those figures and help their customers to make a fair comparison, those customers will choose leather.

In your comments, you also said that automotive leather remained uncertain because of factors outside the control of the leather industry. What would you say to offer encouragement to companies producing leather for the car industry?

It’s what we have said already: carbon footprint. Car-makers don’t have the right information about impacts either. But no car company, except Tesla, has stopped offering at least some of their car seats in leather, so far. I know Volvo has said it will do this, but I don’t think it has done so yet. We need to give those companies good, accurate, science-based information about the impact of leather so that they will continue to use it.

From an IULTCS point of view, which are the areas in which you hope to see progress during your time as president?

I hope to see progress in the regulation of chemicals under REACH. There are new demands to decrease the permitted quantities of bisphenol and other chemicals. Some luxury groups have reacted to this by telling tanners that they don’t want them to use bisphenol any more. But they are confusing bisphenol A, which is toxic but not in use in the leather industry, with bisphenol F and S. Our job at IULTCS is to communicate the truth about these products.

What is the best way to achieve that?

Our role is to set up the right test methods. Today, there is no effective test method for checking the quantities of bisphenol F and S in leather. The tests in place are no good. We must try to set up a better test method and make sure it becomes the standard. If we don’t, tanners will face problems in making leather, as they have with chrome VI. The European Commission said two years ago that it wanted to push the concentration limit of chrome VI from 3 ppm to 1 ppm, but it does not make sense. We have to talk to the Commission to make it clear that what it is asking for is not reasonable. This dialogue is very important. I fear that the only people talking to the decision-makers are campaign groups with an agenda and that government ministers and other people in authority listen to what these groups say without checking it with specialists. I’m trying to be more proactive as IULTCS president, trying to prevent these difficulties from arising. It’s a big task and we are doing our best, but the leather industry is not very well known by the authorities.

Jean-Pierre Gualino, IULTCS president