Federico Brugnoli: Lifecycle thinking

Innovator and entrepreneur Federico Brugnoli, the founder and chief executive of Milan-based consultancy Spin360, has been involved for years in innovation in the leather industry and other sectors, always aiming to promote sustainable business models. He was also one of the main architects of European leather’s product environmental footprint category rules. He explains here that his focus has now moved on from mere lifecycle assessment (LCA) to a new philosophy he calls lifecycle thinking.

Why is it important for leather manufacturers to keep thinking about innovation and investing in innovation during this time of, let’s hope, recovery from the effects of the covid-19 pandemic?

The pandemic has been an accelerator for many processes that were undergoing change naturally; the changes are now going much faster. Innovation is the key for moving onwards. There is no other way out except either dying or innovating. What we innovate is the question that everybody has. If we look at a broader spectrum, I think a lot of innovation should be on the side of sales, the hybridisation of relationships with customers, exploiting the digital potential. But it’s not about leaving everything to digital because leather is still a material that has to be felt, experienced with at least four of the five senses.

What does hybridisation mean in this context?

It’s a new way of engaging with the customer. If we speak about hybridisation in retail, it means something that is also called ‘phygital’, meaning physical and digital. Leather manufacturers could evolve by partnering with logistics companies to send samples and have digital meetings while people in different parts of the world feel the samples. It’s a new way of allowing customers to touch and feel leather and at the same time avoid travelling. Trade shows are cancelled or they are digital, so how is leather going to be selected or improved or prototyped? This is making things very difficult, especially at the high end of the market, where seasons are still important, where product development is crucial and where people were used to meeting during the year to check the possible evolution [such as the development of new ranges]. In high-end luxury, we have had Lineapelle doing two main fairs and two small ones every year. Première Vision was the same. How are they going to replace this? This is still a question in a period of uncertainty, when nobody knows what’s going to happen in the next six months. We have also been working on innovation in terms of sustainability. At Spin360, we have been looking at lifecycle design of products, conceiving leather to be sustainable, not assessing the numbers afterwards but using the numbers and the techniques of lifecycle assessment (LCA) to design processes and products a priori.

What is your assessment of the levels of financial and other help available to companies in the European Union to support recovery and what is the best way for SMEs (which includes most tanners) to claim some of that support?

Something that is expected in the next few months is the so-called EU recovery fund. It will be based on several pillars, among which will be “greening the economy” or the Green Deal. Another will be digitalisation. We don’t know how much impact it will have, but we expect a lot of public funds to become available. There are some key values. I speak for European tanners, but also in general for the European leather-linked sector. I include footwear and leathergoods production in Europe. There are a lot of keywords that have links to the EU recovery fund that are typical of these industries, things like craftsmanship and investment in innovation. Digitalisation of processes is also important because if, 10 years ago, tanners were to sell a square-metre of leather, the documents accompanying it were, basically, price, delivery-time, quality and physical tests. Now you have physical safety, chemical safety, PRLs (prioritised requirements lists), MRSLs (manufacturing restricted substance lists), PRSLs (product restricted substance lists), LCA. The amount of information going with the product is increasing. Everybody speaks about blockchain, but blockchain does not apply yet to a set of parameters that are key and very important for leather makers, all the ones related to product performance, product compliance and sustainability parameters.

When you say that this does not apply to blockchain yet, it implies that, one day, blockchain will be able to help tanners. You must have a way of explaining what blockchain is and how it can help.

Well, very simply, blockchain is a technology that is able to connect very rapidly and in a consistent and reliable manner information that is available in tanneries, in companies. By available I mean that this information is already in the ERP (enterprise resource planning) system, the informative systems that companies have. If companies have a well developed ERP, they have all the advancement of production, all the different production logs, costing, delivery-time, bill of materials, everything that is in the informative system. So blockchain is able to pick information from all these systems and make it easily available. Blockchain can be linked to traceability, for example. But the point is that much of the information, and traceability is an example of this, is not yet in the informative systems, the ERP that companies have. We at Spin360 have developed a software platform and we are collecting monthly information on traceability from nearly 100 tanneries, but they still need to provide this information outside of a blockchain scenario because it is not embedded in the normal systems.

We know a little about some of the other support programmes, including ELIIT, and about your involvement in a project called Leather Smart LCA. What is the idea behind this project?

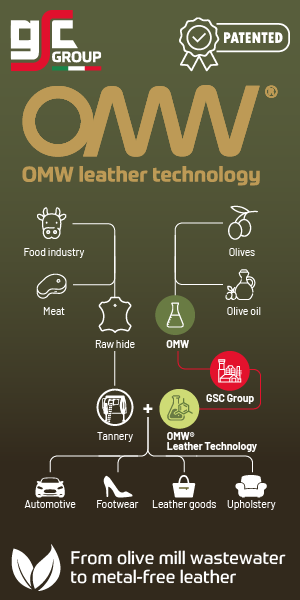

ELIIT is for small and medium businesses that have the ability to innovate but not with really high-end objectives, but more down-to-earth, achievable objectives. I was just holding a workshop this morning on ELIIT and I said that these are the kind of projects that tanners can really benefit from. It’s not a lot of money [€70,000], but it is very focused, with objectives that are close to the market. Smart LCA is a project aimed at developing two important technologies. One is an advanced software for lifecycle assessment and lifecycle costing. Basically, an existing process is run, then we analyse the data. When I speak about analysing data, I mean that, for a normal product, we can collect more than 2,700 environmental indicators. We apply algorithms that allow us to make what we call hotspot analyses, the identification of the most important contributors to impact. It’s not AI (artificial intelligence) yet but we hope to get there very soon. We can suggest what it’s best to focus on and formulate a hypothesis for improvement. The second part is the concept of a smart drum. We have a prototype of that technology and, with the simulation we have done, we can make some hypotheses. We can use the figure for the environmental impact of the chemistry, we can reduce the running-time, we can reduce the usage of water. This hypothesis can be checked in an R&D (research and development) drum and if the product goes okay, then the improvements can be industrialised (scaled up). The smart drum is a tool for a science-based approach to tanning. The power of this way of thinking is that, apart from LCA, we can do lifecycle costing.

When we talk about leather and lifecycle analysis or lifecycle assessment, it’s impossible not to think about the years of work you contributed to helping the leather industry secure European Commission approval of product environmental footprint category rules (PEFCR) in 2018. We hoped that achievement would end the debate about leather’s carbon footprint, but it hasn’t. Why not? How can Veja announce that its leather has a carbon footprint of 100.5 kilos of CO2-equivalent per square-metre when the figure UNIC gives as an average for Italy is 1.9 kilos?

It looks like the industry is coming towards a convergence of the most important factors that influence carbon footprint. LCA is a complex discipline and is based on science. It has to be done by professionals. Just to communicate a number doesn’t mean much. The amount of data required to carry out a proper assessment is vast, and data quality is very important. I am trying to move as far away as possible from presenting single numbers in this debate now. We are moving into a new philosophy. If you take the work assessment, it means that you are assessing what you have done in the past. We are working on the concept of lifecycle thinking. That is to say the numbers that are coming out are not the end of the work. They are the start of an improvement plan. This is the reason we obtain so many numbers for each product. The important thing is that customers are sitting with the tanners and they’re looking at the impact improvement plans can have on the reduction of carbon footprint. This is what is making them happy. Lifecycle thinking is the new forward, in my opinion. It’s time to move forward.

Immediately before the pandemic, you devoted a lot of time and energy to ideas such as the Innovation Square component at Lineapelle and other initiatives such as Innovation Training. What have these ideas involved and how have they gone?

Innovation Square has involved people from renowned academic organisations all over the world, and we’re still doing it. There is bad news and good news. The bad news is that, most probably, it won’t be possible to organise events at that level in the near future because of constraints in travelling. The good news is that knowledge is becoming more available now. Before, if I had to organise an Innovation Square event, I had to convince famous people to take a plane, come to Milan, be away from their home and office for a week. Now everything is simpler. The network of people with whom we are in touch is willing to keep on sharing their knowledge and their innovations. This will be possible in a digital form. We are thinking also about having digital training done by these people. We call it democratisation of knowledge.

And Innovation Training, when you went with a group of European tanners to visit important technical institutions in the US?

I am still in touch with colleagues on the other side of the Atlantic. We recently organised the online version of the other very big event we do, which is called Micam X. Micam X is now online, accompanying the digital version of the Micam show. We have had people from MIT (Massachusetts Institute of Technology), Harvard, the United Nations. We have had a huge a number of speakers and we created it as a TV show. Everything is recorded in a real studio and it will be broadcast over two months. This is where we are going.

Federico Brugnoli has worked on complex lifecycle assessments for years. He says the figures they produce are just the beginning. Credit: Federico Brugnoli