Thomas Ware celebrates Queen’s Award success

23/04/2018

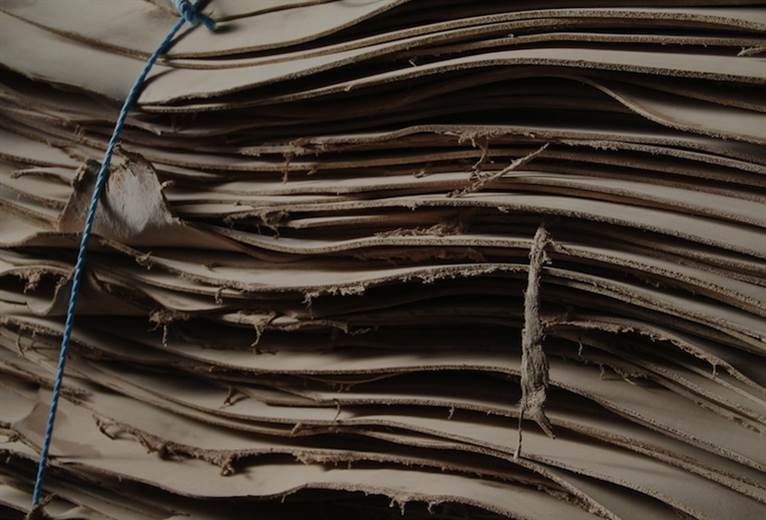

Hides spend 10 days in the Thomas Ware limeyard before sorting, grading, rounding into butts shoulders and bellies, and splitting. Tanning can then take between three months and more than a year, with the raw material soaking in a blend of vegetable tanning materials. At the end of this long process, the material goes into the drying sheds for up to six weeks before going for dressing and finishing. It can take up to 18 months to make some finished leathers.

Around 50% of butts are made into sole leather, the traditional market for leather of this kind, but greater growth has come in recent years from sales of leather for industrial applications, accessories, saddles and other equestrian equipment, and sporting goods, specifically leather to cover cricket balls; this was the basis of the company’s Queen’s Award application.

Managing director, Alistair Brearley, explained on announcing that the company’s bid had been successful: “We’ve been aiming at higher-end niches, such as wallets and belts made out of bridle leather. Plus, our cricket balls and our saddles are top-end. We also have important business in North America, mostly in industrial applications.”

This has helped increase exports from 5% of total revenues six years ago to 37% today, a performance that clearly impressed the Queen’s Award assessors. Geographically, Thomas Ware has increased its business in Japan, India, China and the US, and has dipped its toe into the Australian market too.

“We know we cannot produce in high volumes,” Mr Brearley said, “and we can’t afford to compete on price, but our flexibility and willingness to help mean we are good at meeting our customers’ needs. And what we have achieved, thanks largely to the work that sales development manager, Barry Knight, has done, is develop a few new styles and gone out and sold globally.”

He said his hope is that Thomas Ware customers will be pleased with the leather manufacturer’s success in the Queen’s Award for Enterprise and use it to increase sales of their finished products, with the positive knock-on effect of a further boost to leather consumption.