Lanxess to offer tanners ‘do-it-yourself’ X-Biomer retanning agents

20/03/2017

It will work on the project with German tanner Heller-Leder and Leverkusen-based research group Invite. The project will have a total investment of around €5 million, with 50% of the money coming from Germany’s federal ministry for education and research. Feasibility tests are set to take place with the third project partner, Heller-Leder, at its tannery in Hehlen, Lower Saxony, and a pilot plant should be operational by the middle of this year. Heller-Leder was the winner of Tannery of the Year in 2011.

Lanxess has explained that the pilot plant will involve the use of shavings from the tanning process, material that has mostly gone to waste in the past. It will now use the shavings and “organic biomass” to create retanning agents that it will bring to market as part of the X-Biomer range that the company launched in 2014.

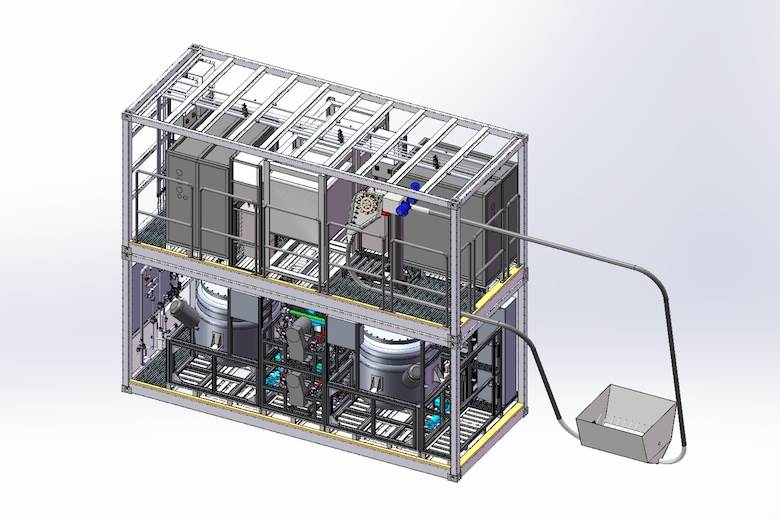

Manufacturing equipment for recycling the shavings can be used on-site at tanneries, allowing leather manufacturers to produce X-Biomer retanning agents on their own. Lanxess has suggested that it may be possible for tanners to lease this equipment from the chemicals manufacturer. According to Lanxess’s calculations, a medium-sized tannery can produce between one and two tonnes of shavings a day. Using the leased equipment, a tanner could manufacture a substantial volume of X-Biomer retanning agents directly on site.

“As one of the largest manufacturers of chemicals for the leather industry, we consider the sustainability of these processes to be of particular importance to us,” said Luis López-Remón, head of the leather business unit at Lanxess, on announcing the development. “Our goal with this project is to highlight how production waste during leather manufacture can be recycled at the tannery, significantly improving sustainability compared to the conventional production of retanning agents in centralised production facilities located far away from the tanneries.”

For his part, Dr Dietrich Tegtmeyer, vice-president with responsibility for leather industry relations at Lanxess and the head of the company’s involvement in this project, said he regards it as “an extremely promising step” towards greater sustainability in leather production. At the time of the announcement he said tanners would be able to save “an enormous amount” on logistics and packaging through being able to produce the retanning agents in situ and on demand.